Sustainability

HELLO! eco!

- What is “HELLO! eco!”?

- Introduction of products with the “HELLO! eco!” mark

- Past Efforts to Reduce Environmental Impact

What is “HELLO! eco!”?

Our commitments originate from each individual’s determination to “start something good for ecology (eco)!” To maintain this determination on a perpetual basis, we have set “HELLO! eco!” as the slogan for our environmental activities.

“HELLO! eco!” Mark

Products that have met the ecology standards that Hisamitsu Pharmaceutical has established will display the “HELLO! eco!” mark sequentially with an explanation in accordance with the Environmental Labeling Guidelines laid down by the Ministry of the Environment. The mark has been designed to represent each individual’s determination to “start something good for ecology!” with the box at the back symbolizing a patch and the “e” of “eco” showing a smile in a simple and positive manner.

We place the “HELLO! eco!” mark on any of the following products:

- Product with reduced packaging weight compared to Hisamitsu Pharmaceutical’s reference product*.

- Products made using raw materials and energy sources (such as plant-derived materials, recycled materials, and renewable energy) that contribute to reducing environmental impact.

- Products which have achieved reduction of environmental burden through the product life cycle compared to Hisamitsu Pharmaceutical’s reference product*.

- * Hisamitsu Pharmaceutical’s reference product: Hisamitsu Pharmaceutical’s conventional or representative products.

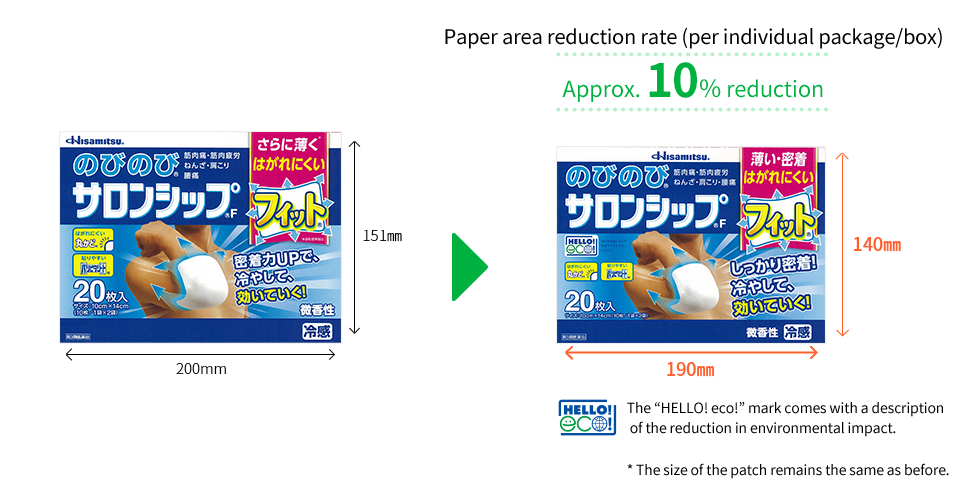

Example of products more compactly packaged than previous ones: NobinobiⓇ SalonsipⓇ FitⓇ 20 Patches

- *We are placing the “HELLO! eco!” mark gradually on our products that satisfy Hisamitsu Pharmaceutical's ecology standards.

- * We are also making the same efforts to reduce environmental impact for prescription drug.

Introduction of products with the “HELLO! eco!” mark

At Hisamitsu Pharmaceutical, we are constantly striving to increase the QOL of patients and improve our products to make them more environmentally friendly, by changing to “eco and compact” packages, developing new packaging, and using environmentally friendly raw materials. Here, we are introducing our products with the “HELLO! eco!” mark.

We are also making the same efforts to reduce the environmental impact of prescription pharmaceutical products.

Products with the “HELLO! eco!” mark

(OTC pharmaceuticals, etc.)

Past Efforts to Reduce Environmental Impact

At Hisamitsu Pharmaceutical, we strive to reduce environmental impact in our value chain, including R&D, production, logistics, and sales. We introduce the main initiatives that we have taken so far to reduce environmental impact.

| Period (Starting Year) |

Description | Effect |

|---|---|---|

| FY2011 | Launch of our modal shift (Replacement with the lower-CO₂-emissions product transportation) |

[FY2024 results] CO₂ emissions reduced by approximately 355 t compared to truck transportation only |

| FY2012 | Reduction in material waste generated in the manufacturing process of MOHRUSⓇ Tapes L40 mg | Reduction in the use of plastic by approximately 35 t per year (compared with the period prior to the launch of this effort) |

| FY2015 | Replacement of current corporate sales vehicles to hybrid models (on a step-by-step basis) | [As of February 2024] Percentage of hybrid models in all corporate sales vehicles: 100% |

| Launch of MOHRUSⓇ Paps XR, whose plaster was reduced by 70% in mass in comparison with MOHRUSⓇ Paps, as a result of product development |

Reduction in the use of plaster by approximately 662 t per year (compared with the period prior to the launch) |

|

| FY2017 | Optimization of a seasonal operation of air conditioner heat source equipment at a Tosu Laboratories (reduction in the use of water resources) |

Reduction in the use of water resources by approximately 25% (compared with the period prior to the launch of this effort) |

| Reduction in the size and weight of the packages for MOHRUSⓇ Tapes and other products | Reduction in the use of paper and plastic by approximately 210 t per year (compared with the period prior to the change) |

|

| FY2018 | Replacement of a kerosene boiler with an electric water heater at a Tsukuba laboratories | Reduction in the use of energy by approximately 20% (compared with the period prior to the launch of this effort) |

| Reduction in the package size of SalonpasⓇ HOT by folding the patch agent into halves | Reduction in the use of plastic by approximately 17 t per year (compared with the period prior to the change) |

|

| FY2019 | Suspension of air conditioning in the clean area at a Tosu Laboratories at night | Reduction in the use of energy by approximately 3% (compared with the period prior to the launch of this effort) |

| Certification of the Hisamitsu Pharmaceutical Museum as a ZEB | Energy-saving operation continued in FY2024 | |

| Reduction in the package sizes of NobinobiⓇ SalonsipⓇ and FeitasⓇ Sip by folding their medicine bags | Reduction in the use of paper by approximately 5t per year (compared with the period prior to the change) |

|

| Launch of the sales of NobinobiⓇ SalonsipⓇ F 10 pieces in medicine bags (adoption of a package-less design) |

Reduction in the use of paper by approximately 8 t per year (compared with the period prior to the adoption of the package-less design) |

|

| Adoption of a capless system for AirⓇ SalonpasⓇ (on a step-by-step basis) | Reduction in the use of plastic by approximately 4 t per year (compared with the period prior to the change) |

|

| Launch of a joint energy project at the Utsunomiya Factory | Reduction in the use of energy by approximately 20% and generation of CO₂ emissions by approximately 20% (Reduction due to cooperation between three business entities) |

|

| FY2020 | Reduction of the package sizes of SalonpasⓇ and MOHRUSⓇ Tapes (on a step-by-step basis) | Reduction in the use of paper and plastic by approximately 150 t per year (compared with the period prior to the change) |

| Digitization of paper brochures for prescription pharmaceutical products (on a step-by-step basis) | Reduction in the use of paper by approximately 10 t per year (compared with the period prior to the digitization) |

|

| Inhouse efforts to go paperless | [FY2024 results] Reduction from FY2019 by approximately 54% in terms of monetary amount and by approximately 56% in terms of number of sheets |

|

| FY2021 | Sales of NobinobiⓇ SalonsipⓇ FitⓇ 10 Patches in a new package(Poke-SipⓇ) | Reduction in the use of paper by approximately 3 t per year (compared with the conventional version*) *NobinobiⓇ SalonsipⓇ F 10 Patches |

| Digitization of package inserts for prescription pharmaceutical products | Reduction in the use of paper by approximately 75 t per year (compared with the period prior to the digitization) |

|

| FY2022 | Additional products (Poke-SipⓇ) to the lineup (1) NobinobiⓇ SalonsipⓇ FH (HOT type) 10 Patches (2) NobinobiⓇ SalonsipⓇ FH (HOT type) 20 Patches (3) NobinobiⓇ SalonsipⓇ Fα (Odorless type) 10 Patches (4) NobinobiⓇ SalonsipⓇ Fα (Odorless type) 20 Patches (5) FeitasⓇ Shippu 10 Patches (6) FeitasⓇ Shippu Onkan 10 Patches (7) NobinobiⓇ SalonsipⓇ FitⓇ 20 Patches (8) NobinobiⓇ SalonsipⓇ FitⓇ 40 Patches |

Reduction in the use of packaging materials by approximately 80% (compared with conventional products*) *(1),(2) NobinobiⓇ SalonsipⓇ FH (FITⓇ Onkan) 16 Patches (2),(3) NobinobiⓇ SalonsipⓇ Fα (FITⓇ Odor-free) 16 Patches (5) FeitasⓇ Shippu 16 Patches (6) FeitasⓇ Shippu Onkan 16 Patches (7) NobinobiⓇ SalonsipⓇ F 20 Patches (8) NobinobiⓇ SalonsipⓇ F 40 Patches |

| Use of recycled PET (80%) and reduction of plastic in packaging bags of MOHRUSⓇ Tapes 20 mg and MOHRUSⓇ Tapes L 40 mg |

Reduction in the use of plastic by approximately 36 t per year (compared with the period prior to the change) |

|

| FY2023 | Additional products (Poke-SipⓇ) to the lineup (1) FeitasⓇZ DicsasⓇ Shippu F 7 Patches (2) SalonpasⓇ Gel-Patch COOL 10 Patches(For Singapore) (3) SalonpasⓇ Gel-Patch HOT 10 Patches(For Singapore) |

Reduction in the use of packaging materials by approximately 80% (compared with conventional products*) *(1) FeitasⓇ Z DicsasⓇ Shippu Reikan 6 Patches (2) SalonpasⓇ Gel-Patch 6 Patches (3) SalonpasⓇ Pain Relieving Gel-Patch HOT 6 Patches |

| Reduction in the height of the can for AirⓇ SalonpasⓇ despite the maintenance of the same capacity (1) AirⓇ SalonpasⓇ Jet α 100mL (2) AirⓇ SalonpasⓇ Jet α 150mL (3) AirⓇ SalonpasⓇ Jet α 300mL (4) AirⓇ SalonpasⓇ DX 80mL (5) AirⓇ SalonpasⓇ DX 120mL |

Aluminum reduction of approximately 1 t per year (compared to the period prior to the change) |

|

| Recycled PET (80%) is used for the outer layer of the packaging bag (1) ESTRANAⓇ Tapes 0.09mg (2) ESTRANAⓇ Tapes 0.18mg (3) ESTRANAⓇ Tapes 0.36mg (4) ESTRANAⓇ Tapes 0.72mg (5) OdorleshipⓇ [onboard ISS (International Space Station)] |

CO₂ emissions reduced by approximately 24% during film production compared to general PET film | |

| Certification of SalonpasⓇ Arena as ZEB Ready | A building that meets the criterion of at least 50% reduction in primary energy consumption compared to standard primary energy consumption, excluding renewable energy |

|

| FY2024 | Achieving a zero product returns policy in the domestic OCT pharmaceuticals business | Effectively using resources and reducing the environmental impact associated with product returns |

| Packaging renewal for FeitasⓇ 5.0 (10 Patches) and FeitasⓇ 5.0 (Oban Size, 10 Patches) to become boxless (to be sold in sachets) (the outer material of the sachets is made of 80% recycled PET, or polyethylene terephthalate) |

• Elimination of the outer box has reduced packaging material usage per individually packaged product by approximately 80% (compared to the previous product) • The 80% use of recycled PET has reduced CO₂ emissions during film production by approximately 24% compared to regular PET film. |

|

| Certification of the SAGA Global Research Center as ZEB Ready | A building that meets the criterion of at least 50% reduction in primary energy consumption compared to standard primary energy consumption, excluding renewable energy |

|

| Packaging simplification and the launch of mailbox-sized products for mail order (1) SalonpasⓇ 160 Patches (2) FeitasⓇ 5.0, 120 Patches |

• Packaging simplification (eliminating individual packaging boxes and packing sachets directly in shipping boxes) has reduced the use of paper resources. • Slim packaging that can be dropped off in a mailbox has reduced CO₂ emissions from redelivery. |

|

| Reducing the amount of plastic used by adopting integrated labels (1) NobinobiⓇ SalonsipⓇ FitⓇ 10 Patches (2) NobinobiⓇ SalonsipⓇ FitⓇ 20 Patches (3) NobinobiⓇ SalonsipⓇ FitⓇ 40 Patches (4) NobinobiⓇ SalonsipⓇ FitⓇα (Odorless type) 10 Patches (5) NobinobiⓇ SalonsipⓇ FitⓇα (Odorless type) 20 Patches (6) NobinobiⓇ SalonsipⓇ FitⓇ H (Hot Type) 10 Patches (7) NobinobiⓇ SalonsipⓇ FitⓇ H (Hot Type) 20 Patches (8) FeitasⓇ Shippu 10 Patches (9) FeitasⓇ Shippu Onkan 10 Patches (10) FeitasⓇZ DicsasⓇ ShippuF 7 Patches |

By adopting integrated labels, the amount of packaging material used per label was reduced by roughly 3.7% | |

| FY2025 | Introducing the uniform recycling system known as “BRING UNIFORMTM" | Recycling used workwear into new resources while reducing CO₂ emissions |

| Recycling MOHRUSⓇTape packaging bags into name tags worn by MRs (medical representatives) | Effective Use of Resources |

For more information on Hisamitsu Pharmaceutical’s environmental commitments, please see the link below.