Sustainability

Environment

- Hisamitsu Pharmaceutical Group Environmental Policy

- Action to climate change

- Reduction in Environmental Impact

Reduction in Environmental Impact

We believe that we have a great corporate responsibility to reduce the environmental impact generated through business operations by addressing problems such as the various emissions from production activities and waste from products after use. We will, of course, continue to comply with environment-related laws and regulations, and at the same time, strive to accomplish voluntary targets by making efforts to use resources appropriately and conserve the natural environment.

Environmental Accounting

Hisamitsu Pharmaceutical compiles environmental accounting in reference to the Ministry of the Environment's “Environmental Accounting Guidelines” in order to quantitatively understand the investments and expenses related to environmental measures and their impact.In FY2024, for the purpose of reducing CO₂ emissions to prevent global warming and saving energy, we continued to promote new installation of solar panels, conversion of lighting fixtures to LED, the upgrade of air conditioners to energy-saving types, and power saving by improving the production operation ratio. Furthermore, we are increasing items with a smaller size of medicine bags, cases, and cardboard boxes for our products (Eco & Compact) and actively promoting the efficient use of resources.

Environmental Conservation Cost(Thousands of yen)

| Category | FY2022 | FY2023 | FY2024 | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Facilities | Expenses | Total | Facilities | Expenses | Total | Facilities | Expenses | Total | |

| Pollution prevention | 0 | 33,164 | 33,164 | 0 | 46,402 | 46,402 | 0 | 23,236 | 23,236 |

| Global environmental protection | 307,300 | 98,274 | 405,574 | 274,390 | 174,596 | 448,986 | 432,948 | 143,022 | 575,970 |

| Resource recycling | 273,708 | 155,529 | 429,237 | 172,858 | 166,701 | 339,559 | 172,357 | 151,284 | 323,641 |

| Upstream/Downstream | 0 | 16,359 | 16,359 | 0 | 20,119 | 20,119 | 0 | 18,669 | 18,669 |

| Management activities | 0 | 68,214 | 68,214 | 0 | 68,150 | 68,150 | 0 | 63,198 | 63,198 |

| Social activities | 0 | 5,914 | 5,914 | 0 | 4,897 | 4,897 | 0 | 919 | 919 |

| Environmental damage response | 0 | 488 | 488 | 0 | 482 | 482 | 0 | 235 | 235 |

| Other | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Total | 581,008 | 377,942 | 958,950 | 447,248 | 481,347 | 928,595 | 605,305 | 400,563 | 1,005,868 |

Scope: Hisamitsu Pharmaceutical on a non-consolidated basis

Environmental Conservation Effect

| Category | Unit | Environmental impact volume | Increase/decrease in environmental impact volume (vs. FY2022) |

||||

|---|---|---|---|---|---|---|---|

| FY2022 | FY2023 | FY2024 | FY2022 | FY2023 | FY2024 | ||

| Energy consumption (crude oil equivalent) |

kL | 11,844 | 10,976 | 11,445 | 100% | 93% | 97% |

| CO₂ emissions | t | 22,140 | 22,468 | 21,814 | 100% | 101% | 99% |

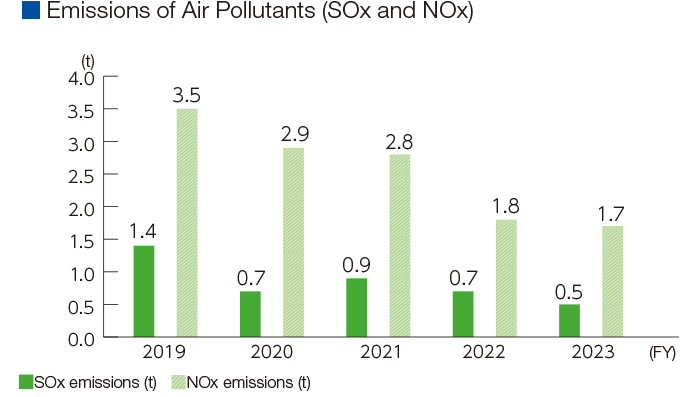

| SOx emissions | t | 0.7 | 0.5 | 0.003 | 100% | 71% | 0% |

| NOx emissions | t | 1.8 | 1.7 | 0.4 | 100% | 94% | 22% |

| Water withdrawal | 1,000㎥ | 174 | 173 | 186 | 100% | 99% | 107% |

| Wastewater discharge | 1,000㎥ | 87 | 87 | 98 | 100% | 100% | 113% |

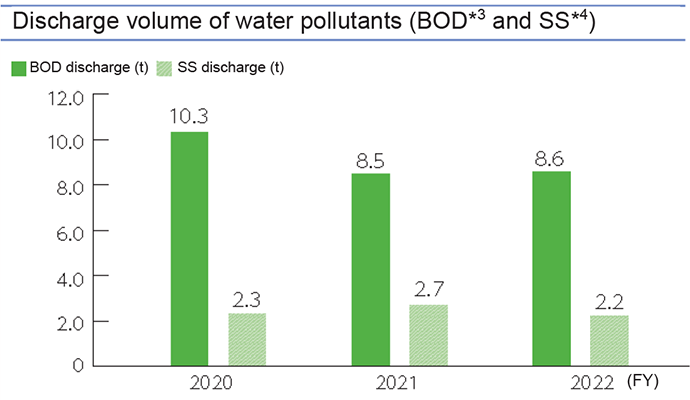

| BOD emissions | t | 8.6 | 10.3 | 9.1 | 100% | 120% | 106% |

| Waste emissions | t | 3,722 | 3,358 | 3,329 | 100% | 90% | 89% |

Scope: Hisamitsu Pharmaceutical on a non-consolidated basis

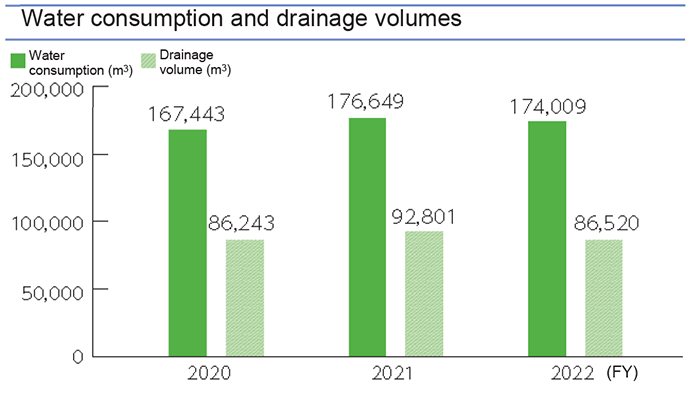

Water Resources Management

Water resources are essential to business operations. We believe that it is integral to use finite water resources more effectively and reduce our environmental impact. We conserve water resources by properly managing both water usage and drainage volumes.

Response to water risks

In the Hisamitsu Pharmaceutical Group, an assessment of water stress, which is an indicator of water scarcity, was conducted on domestic and overseas production sites and R&D sites using WRI Aqueduct,* which is a tool for assessing the water risks around the world. As a result, we verified that there were no sites that were evaluated as “High” or “Extremely High” in water stress. (As of June 2025).

There were also no sites where water restrictions or problem caused by water scarcity occured, so we recognize that there is no urgent water shortage risk.We will continue to assess water risks and work on the efficient use of water resources and the reduction of water usage.

*A tool for assessing water risks provided by the World Resources Institute (WRI)

https://www.wri.org/aqueduct (External link)

Evaluation of Water Stress Using WRI Aqueduct

| Water stress level | Base |

|---|---|

| Low (<10%) |

Hisamitsu Brazil |

| Low - medium (10 - 20%) |

Tosu Factory, SAGA Global Research Center, Noven, Hisamitsu Vietnam, Hisamitsu Indonesia |

| Medium - high (20 - 40%) |

Utsunomiya Factory |

| High (40 - 80%) |

N/A |

| Extremely high (>80%) |

N/A |

Resource Recycling

We think that we should fully consider the effective use of limited resources in business management. We promote the reduction of resource input, waste recycling, and the use of renewable raw materials as well as striving for pollution alleviation and the proper management of chemicals.

Recycling

Production waste generated in the manufacturing process (including waste plastics) is used in thermal recycling as a heat source for a cement factory and other facilities.Ash generated after incineration is used as a resource to be mixed with cement and other materials, leading to a 100% recycling rate for waste plastics in FY2024. Moreover, transportation materials after use such as cardboard are separated and collected by category and recycled as raw materials for recycled paper and as a cushioning material.

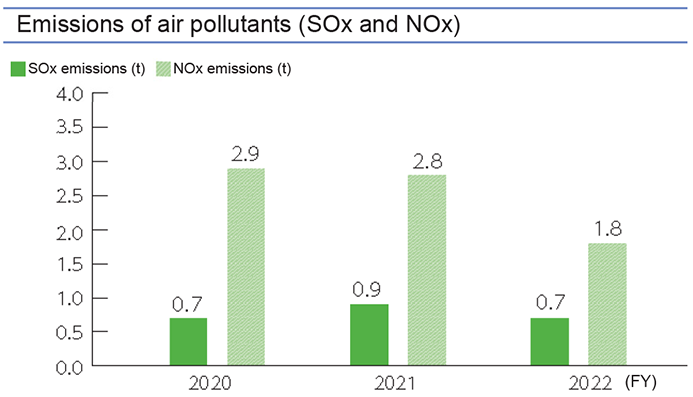

Management of Air Pollutants

SOx (sulfur oxides) and NOx (nitrogen oxides), which are emitted during the operation of boilers and private generators, cause air pollution. In order to reduce the emission of these pollutants, we are upgrading our equipment and gradually replacing our fuel from heavy oil with city gas. We comply with our self-imposed regulations, which are more stringent than the standards stipulated under the Air Pollution Control Act, and we confirm that the emission of these pollutants are below the levels set in our regulations.In FY2024, we consolidated research functions previously distributed across two sites; namely the Tosu Research Institute and Tsukuba Research Institute, which were relocated to the SAGA Global Research Center. Alongside this relocation, we switched to a smaller-scale boiler system with lower combustion capacity, thereby achieving reduced levels of air pollutant emissions (SOx and NOx).

*SOx and NOx values are totals for the Kyushu Head Office, Utsunomiya Factory, and Tsukuba Laboratories, which have large environmental impacts.

Management of Specified Chemical Substances

Hisamitsu Pharmaceutical manages chemical substances appropriately in accordance with the Act on Confirmation, etc. of Release Amounts of Specific Chemical Substances in the Environment and Promotion of Improvements to the Management Thereof (Pollutant Release and Transfer Register / PRTR system*1). The chemical substance subject to reporting was toluene, with a handling volume of 1.3 t and an atmospheric emission volume of 0.1 t in FY2024.We will continue to strive for appropriate use and management (storage and disposal*2) of the substance to reduce the environmental impact.

*1 PRTR system: A system established under the “Act on Confirmation, etc. of Release Amounts of Specific Chemical Substances in the Environment and Promotion of Improvements to the Management Thereof” that requires the release amounts of certain chemical substances into the environment to be monitored and reported to the government

*2 Waste disposal:

・Waste liquid treatment

After use, the waste liquid is entrusted to a waste disposal contractor for proper disposal.

・Combustion treatment

Some manufacturing processes generate gases containing toluene. The gas is cooled and not collected as liquid waste but combusted using a gas combustion system (oxidative decomposition method).

Handling Volume of PRTR Substances( t )

| FY2022 | FY2023 | FY2024 | ||

|---|---|---|---|---|

| Toluene | Handling volume | 3.7 | 3.4 | 1.3 |

| Emission into the air | 0.2 | 0.2 | 0.1 | |

| Waste disposal | 3.5 | 3.2 | 0.2 | |

Efforts to Go Paperless within the Company

We are making efforts to go paperless across the Company by minimizing paper use for the reduction of environmental burden and using IT (digitization). As a result, in FY2024, we reduced the amount of paper purchased by around 54% in value terms and around 56% in terms of the number of sheets compared to FY2019. We will continue to promote paperless operations in the future.

Emergency Drill

Simulating emergency situations, such as equipment damage and malfunction, operational errrors, and natural disasters, including earthquakes, typhoons, lightning, and flooding, we assess the types, scopes, and the severity levels of the impact that such emergencies are expected to have on the environment. Based on the assessment results, we formulate an action plan for contingencies to be handled with high priority and conduct emergency drills at least once a year. This enables us to prepare for minimizing the impact on the environment and our neighborhood.

By confirming through such drills how to respond in the initial phase and how to prevent the spread of damage, we are striving to improve our emergency response capability.

Checking a hydrogen gas leakage detector

List of Simulated Emergencies

| Simulated emergencies | Equipment | Departments | ||

|---|---|---|---|---|

| Fuel leakage | Boiler | Tosu Factory | SAGA Global Research Center | |

| Private power generator | Tosu Factory | SAGA Global Research Center | ||

| Hazardous substance leakage | Indoor facility or room for storing hazardous substances |

Tosu & Utsunomiya Factories | SAGA Global Research Center | |

| Outdoor hazardous substance storage tank | Tosu & Utsunomiya Factories | - | ||

| Hydrogen gas leakage | Hydrogen gas cylinder and piping | Quality Management Department | SAGA Global Research Center | |

| Abnormal exhaust smoke | Boiler | Tosu Factory | SAGA Global Research Center | |

| Private power generator | Tosu Factory | SAGA Global Research Center | ||

| Liquid waste leakage | Waste storage area | Tosu & Utsunomiya Factories | SAGA Global Research Center | |

| Factory effluent leakage | Factory effluent tank | Tosu & Utsunomiya Factories | - | |

| Laboratory effluent leakage | Laboratory effluent tank | - | SAGA Global Research Center | |

| General effluent leakage | General effluent tank | Tosu & Utsunomiya Factories | - | |

Internal Communication

●Commitments to Raising Employees’ Environmental Awareness

At Hisamitsu Pharmaceutical, we are raising the environmental awareness of employees, especially at the Kyushu Head Office, the Utsunomiya Factory, and the SAGA Global Research Center, whose operations have a large environmental impact.While requiring the office and the factory to incorporate environmental training as part of their ISO14001 environmental targets, we also provide a wide variety of environmental training for our overseas business bases. In addition, we share environmental information through our inhouse website at appropriate timing so that the employees of our group companies worldwide will become more aware of environmental issues.

Commitment to Biodiversity

Some raw materials used for our products are derived from natural resources. In terms of sustainable procurement of raw materials, we think the conservation of ecosystems, including biodiversity is important.We are helping to conserve long-tail irises, designated as a 1A threatened species. Since 2015, we have been managing and nurturing this species’ seedlings from Kuboizumi-machi, Saga Prefecture on the premises of the Kyushu Head Office.

Environmental Impact Reduction at Overseas Factories

At our overseas factories, various measures are taken to reduce the use of water and the generation of waste as in the case of our domestic factories. They are working toward reducing environmental impact by raising the awareness of each of their employees of such impact.

| Overseas factories | FY2022 | FY2023 | FY2024 | |

|---|---|---|---|---|

| Noven | Water withdrawal(㎥) | 22,240 | 20,365 | 31,081 |

| Total waste generated (t) |

399 | 156 | 0 | |

| Hisamitsu Vietnam | Water withdrawal(㎥) | 50,519 | 54,627 | 33,871 |

| Total waste generated (t) |

363 | 280 | 0 | |

| Hisamitsu Indonesia | Water withdrawal(㎥) | 17,051 | 32,378 | 31,950 |

| Total waste generated (t) |

444 | 448 | 0 | |

| Hisamitsu Brazil | Water withdrawal(㎥) | 9,067 | 480 | 480 |

| Total waste generated (t) |

638 | 359 | 0 | |

| Total | Water withdrawal(㎥) | 98,877 | 107,850 | 97,382 |

| Total waste generated (t) |

1,844 | 1,243 | 0 |

*Aggregation period: From January to December of each fiscal year

Environmental Commitments at Overseas Factories

●Efforts at Overseas Subsidiaries

- Noven is continuing its activities under the principles of sustainable improvement, target achievement, and uncompromised growth, while organizing green-activity teams for the purpose of efficient energy use and waste management for resource conservation. In FY2023, we replaced 10 aging heating, ventilation, and air conditioning units at the East and West plants with new, high-efficiency ones in an effort to reduce energy consumption. Furthermore, as part of our measures to reduce power consumption in FY2024, we shut off nighttime lighting except for the absolute minimum necessary, as long as it did not compromise the safety of security staff. Additionally, since Miami¾where our office is located¾has a high degree of humidity, turning off the air conditioning could potentially damage equipment and other facilities. Therefore, it runs continuously, but adjusts the set temperature at night since that drops below daytime levels.

- Hisamitsu Vietnam is continuing to reduce electricity consumption by regularly applying thermal barrier coatings to factory roofs to reduce air conditioning loads through the suppression of roof temperatures. We are also working to reduce plastic waste by collaborating with manufacturers to reuse and refill empty containers for neutralizing agents used in the sewage treatment process.

- Hisamitsu Indonesia is continuing to reduce waste by decreasing the size of the inner bag, case, and cardboard of ByeBye-FEVERⓇ made by Hisamitsu Indonesia, which was launched in February 2022, and by eliminating the package insert for SalonpasⓇ GEL, SalonpasⓇ Cream, and SalonpasⓇ Cream HOT, which began to be shipped in October 2022.In addition, we are committed to reducing CO₂ emissions by switching our boiler fuel from diesel to gas in 2024.

- Hisamitsu Brazil is working to reduce its environmental impact in collaboration with companies from Japan that are members of the Japanese-Brazilian Chamber of Commerce and Industry of Amazonas in Manaus.Within the company, we have converted boiler fuel from diesel fuel to gas and are currently working to adopt renewable energy sources. Additionally, we use eco-friendly materials such as recycled paper and plastics for promotional goods while also distributing eco-bags and water bottles made from recycled materials to employees, fostering a greater sense of environmental awareness among our workforce.