Sustainability

Society

EHS Management

At Hisamitsu Pharmaceutical, we have established an EHS management system at the Kyushu Head Office and the Utsunomiya Factory in order to manage and carry out our commitments to the environment (E), health (H), and safety (S) in an integrated manner. As a member of the global society, we will continue to work hard to help conserve the environment and increase safety and health.

*EHS:Environment, Health and Safety(Environment and health and safety)Hisamitsu Pharmaceutical’s EHS Philosophy

Guided by the corporate philosophy “Delivering a Better QOL to the World,” we aim at “Promoting ‘TE-A-TE’ Culture Worldwide,” thereby actively contributing to people’s good health.

Our contribution to conserving the global environment and improving the safety and health of our employees and local communities coincides with our corporate philosophy, and constitutes our most important responsibility.

As a member of the global society, we are actively committed to conserving the environment and improving safety and health, thereby contributing to achieving a sustainable society.

EHS Policy

To achieve the EHS Policy, the Kyushu Head Office and Utsunomiya Factory has set the purpose and goals of EHS, and employees in all divisions shall work together to promote EHS management. Additionally, the purpose and goals of EHS will be reviewed regularly and revised as necessary to ensure continuous improvement.

Kyushu Head Office and Utsunomiya Factory Environmental, Health, and Safety (EHS) Policy

【Environmental Policy】

- 1.Reduce resource use, energy use, and waste generation actively and aggressively;

- 2.Purchase raw materials, equipment, and facilities in full consideration of their impact on the environment;

- 3.Strive to achieve environmental friendliness when developing and improving products;

- 4.Comply with all environment-related laws, regulations, agreements, etc., and strive to prevent environmental pollution;

- 5.Actively participate in local communities’ environmental conservation efforts, and contribute to conserving the global environment; and

- 6.Provide training to raise employees’ understanding and awareness that ensures outcomes of environmental conservation initiatives

【Safety and Health Policy】

- 1.Prioritize creation of environment where employees can work safely and securely, and aim for rewarding workplaces where employees are highly motivated;

- 2.Actively proceed with safety and health risk reduction efforts in all business operations, including R&D, Production, and Sales, and strive to prevent occupational and other types of accidents, prevent employee illness, and maintain and improve their good health;

- 3.Consider safety and health when developing and improving products and technologies;

- 4.Comply with laws, regulations, agreements, etc. related to occupational safety and health, and strive to improve the occupational safety and health management level;

- 5.Promote internal communication with employee participation, as well as external communication such as information disclosure;

- 6.Conduct emergency drills on a regular basis to prepare for natural disasters and other forms of emergencies;

- 7.Contribute to the improvement of health and safety in the community;

- 8.Continue to provide training to improve the knowledge and understanding of our employees to ensure the results of our safety and health activities.

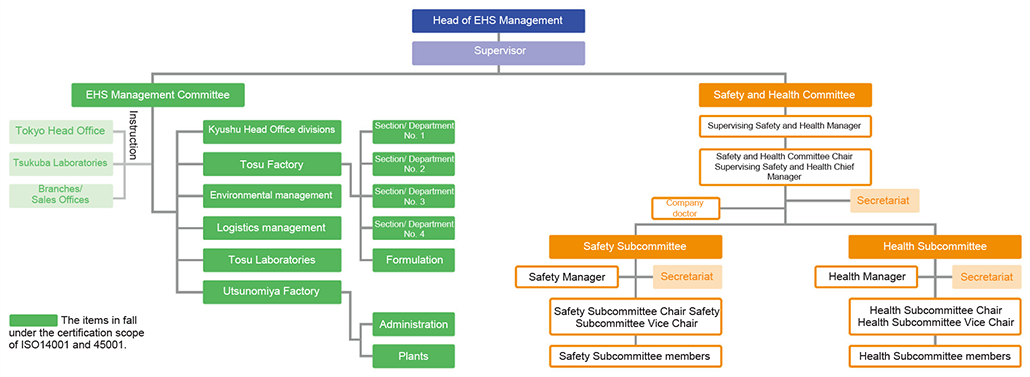

EHS Management Structure

Hisamitsu Pharmaceutical has established the EHS Management Committee and the Safety and Health Committee to manage environmental matters/occupational safety and health and set up the Supervisor position to oversee and manage these committees. The committee meets regularly to set mid-term targets, report on performance, identify risks and opportunities, and discuss management system operations, among other issues, in order to ensure the efficient operation of the EHS.

EHS Management Structure

Management Structure of Occupational Safety and Health

In line with the Industrial Safety and Health Act, we have established a Safety and Health Committee at each of our business bases with consideration given to its scale and features. Led by the Supervising Safety and Health Chief Manager, the committee works to prevent workplace accidents and health problems.

We have a workplace patrol conducted by a company doctor and members of the Health Subcommittee and the Safety Subcommittee on a regular basis, in order to identify problems with safety and health and make the necessary improvements. Moreover, we call monthly meetings of the Safety and Health Committee to deliberate and share information on measures against health problems, as well as the causes of and measures against workplace accidents. While ensuring cooperation between labor and management, we are striving to form an environment in which all employees can work safely and securely.

The Kyushu Head Office and the Utsunomiya Factory, certified under ISO45001, are operated in accordance with an EHS management system.

Commitments by the Safety and Health Committee

While striving to prevent accidents by conducting risk assessments, we are also raising employees’ awareness in order to reduce workplace accidents.

We have a weekly workplace patrol conducted by members of the Safety and Health Committee in order to identify points to be improved from the perspectives of safety and health.

We also measure the levels of noise, dust, luminous intensity, etc. on a regular basis to check our workplace environment, thereby managing the environmental standards and making any necessary improvements. In addition, in the case of workplaces in which organic solvents are used, we are improving the operating environment, while instructing the operators to manage their protective gear appropriately.

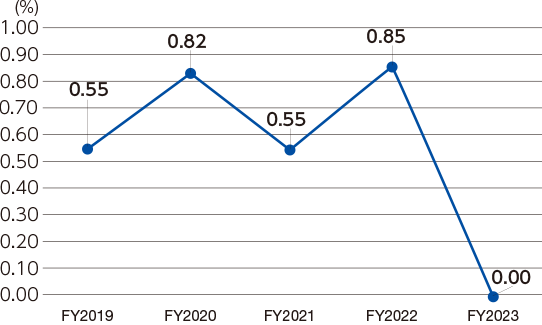

In FY2023, there were eight workplace accidents, with a frequency rate of 0.00%.

Frequency of occupational accidents

EHS Commitments

●Environmental Commitments

In response to societal environmental challenges such as climate change mitigation and the promotion of a circular economy, the Company has set single-year and mid-term goals for resource conservation, energy conservation, and waste reduction to conserving environment.

●Occupational Safety and Health Commitments

- ・To prevent occupational accidents, risk management is promoted through identification of hazardous sources and risk assessment in the workplace. In addition, education is continuously provided to employees to enhance awareness and understanding.

- ・Similar to the environment, single-year and mid-term goals have been set to improve the work environment through workplace patrols and to encourage employees to take paid leave, to create a healthy and comfortable working environment for our employees.

EHS Targets and Results(FY2023)

In FY2023, we satisfied our targets for almost all major themes, such as reducing both resource use and energy use, which are part of our EHS Policy. In FY2024, we set new single-year targets. We will continue our efforts with a focus on performance.

| EHS Policy | Objective (Mid-Term Target) (FY2024) | FY2023 Annual Target | FY2023 Major Results |

|---|---|---|---|

| Reduce Resource Use | (1) Promote resource saving in accordance with the themes of KAIZEN activities. (2) Promote effective use of water resources. |

(1) Proceed with at least one theme that will lead to reduction in resource use. (with at least 80% of the theme[s] achieving the targets) (2) Promote efficient use of water resources. |

(1) Activities were carried out in accordance with 22 themes that led to resource conservation, such as reduction of product loss. (2) The usage of water resources was surveyed, and it was confirmed that there was no wasteful use. |

| Reduce Energy Use | (1) Reduce specific energy consumption at the Kyushu Head Office and the Utsunomiya Factory by at least 3% from the FY2022 results. (2) Reduce CO₂ emissions by 35% from the FY2013 result. (3) Promote enhancement of energy efficiency. |

(1) Reduce specific energy consumption at the Kyushu Head Office and the Utsunomiya Factory by at least 1% from the FY2022 results. (2) Reduce CO₂ emissions by 515.4 [t-CO₂] from the FY2013 result. (3) Promote enhancement of energy efficiency. |

(1) The specific energy consumption at the Kyushu Head Office and Utsunomiya Factory decreased to 98.9% compared to the FY2022 results. (2) CO₂ emissions decreased by 29.5% compared to the FY2013 results. (3) The renewal of chillers in the A-5 building, replacement with highly efficient air-conditioners, and the use of LED lighting were proceeded. |

| Reduce Waste Generation | Reduce waste in accordance with the loss reduction theme of KAIZEN activities. | Carry out activities in accordance with this fiscal year’s loss reduction theme of KAIZEN activities. | Activities were carried out in accordance with 15 themes that lead to waste reduction, including loss reduction in plants. |

| Green Procurement | Use raw materials, building materials, equipment, and transportation services with less environmental impact. | (1) Use raw materials, building materials and equipment with less environmental impact. (2) Use transportation services with less CO₂ emissions. (3) Select environmentally friendly raw material suppliers. |

(1) Achieved at least 90% of the green procurement rate for office supplies. (2) Continued to implement a modal shift. (3) Inspected whether our manufacturing contractors operated in consideration of the environment, safety, and health and thereby confirmed their circumstances. |

| Compliance with Laws and Regulations Related to the Environment/occupational Safety and Health and Prevention of Environmental Pollution | Comply with laws and regulations related to the environment/occupational safety and health, and maintain zero violation of voluntary criteria in environmental assessment data. | Comply with laws and regulations related to the environment/occupational safety and health, and maintain zero violation of voluntary criteria in environmental assessment data. | There were no violations of voluntary criteria in environmental assessment data. |

| Development of Environmentally Friendly Products | (1) Assess environmental impact in the process of product R&D, and promote development of environmentally friendly products. (2) Promote environmentally friendly product specifications (HELLO! eco!). |

(1) Assess environmental impact in the process of product R&D (reduction of resource use, sorting waste, use of no hazardous materials, etc.), and promote development of environmentally friendly products. (2) Promote environmentally friendly product specifications (HELLO! eco!). |

(1) Conducted two assessments during the R&D process of products that led to reduce environmental impact. (2) Changed PET used for drug packaging PET to recycled PET for two items. |

| Conserve Environment in Local Communities | Promote environmental conservation activities in local communities and biodiversity conservation. | (1) Carry out environmental conservation activities in local communities. (2) Continue to conserve biodiversity. (3) Donate to environmental organizations through the Hisamitsu-Hot-Heart Club (for at least five cases). |

(1) Organized clean-up campaigns in the areas around our business sites and participated in clean-up campaigns by local governments. (2) Participated in activities to conserve biodiversity twice. (3) Donated to environmental organizations through the Hisamitsu-Hot-Heart Club. |

| Continuously Improve Environment Safety and Health Management Systems | Improve the operations and efficiency of the EHS management system. | (1) Continue to improve the EHS management system and increase its efficiency. (2) Conduct EHS periodic review to improve the operations. |

(1) Implemented the cycle of Goal planning −> Implementation −> Management review −> Corrective actions, and promoted continual improvement and efficiency improvement. (2) Conducted EHS audit twice a year (in June and February). |

| Prevent Occupational Accidents | To prevent occupational accidents, risk management is promoted through identification of hazardous sources and risk assessment. (Zero lost worktime injuries for four days or more) |

(1) Conduct regular patrols and interviews with workers based on unified safety rules, and promote activities to reduce occupational accidents. (2) Continue to identify risk factors and conduct risk assessments, thereby reducing risks (Zero Level IV accidents under the risk assessment). |

(1) Conducted risk assessment once a year and identified new risk factors. Safety and Health Committee and Safety Subcommittee carried out safety patrols. Promoted risk mitigation activities. (2) Conducted weekly workplace patrols in rotation to reduce occupational accidents. |

| Ensure Employees’ Good Health and Establish a Safe Workplace Environment | Promote employees’ good mental and physical health and the establishment of safe workplace environment. | (1) Improve workplace and work environment. (2) Reduce overtime work and promote the use of paid holidays. |

(1) Broadcasted “No Overtime Day” every Wednesday. (2) Ensured holidays in three consecutive days and encouraged those who had not taken them. |

| Promote Education and Training on Environment and Health and Safety | Conduct education and enlightenment activities on environment and health and safety in a proactive and systematic manner in order to raise employee’s awareness. | (1) Conduct training on safety and health management in a systematic manner. (2) Conduct environmental education in a systematic manner. |

Conducted training on 10 themes related to safety and health management. Disaster drills were conducted twice a year for evacuation and emergency response in the event of a disaster, and emergency response drills on operations were also conducted at each workplace. |

FY2023 Results

Of the 110 EHS targets set for FY2023, we achieved 105, with our achievement rate reaching 96%.

Achievement Rate by Fiscal Year

| FY2019 | FY2020 | FY2021 | FY2022 | FY2023 | |

|---|---|---|---|---|---|

| EHS targets | 153 | 172 | 179 | 139 | 110 |

| Achieved targets | 140 | 154 | 164 | 127 | 105 |

| Achiev ement rate(%) |

92 | 90 | 92 | 91 | 96 |

FY2023 Achievement Rate by Targets

| Targets | Achievement rate(%) |

|---|---|

| Reduce resource use | 94 |

| Reduce energy use,Reduce waste generation | 84 |

| Green procurement | 100 |

| Compliance with laws and regulations related to the environment/occupational safety and health and prevention of environmental pollution | 100 |

| Development of environmentally friendly products | 100 |

| Conserve environment in local communities | 100 |

| Continuously improve environment safety and health management systems | 100 |

| Prevent occupational accidents | 100 |

| Ensure employees’ good health and establish a safe workplace environment | 92 |

| Promote education and training on environment and health and safety | 100 |

| Total | 96 |

Safety Management of Chemical Substances

When a new chemical substance is used at a laboratory or factory of Hisamitsu Pharmaceutical, we ensure that its safety is assessed at the relevant department and make the chemical substance fully known to all employees who will handle it, thereby striving to prevent accidents. In June 2016, when the revised Industrial Safety and Health Act entered into force, it became obligatory to evaluate chemical substances from the perspectives of their danger and potential harm. Accordingly, today, we check the inventory of the chemical substances that we use at appropriate timing and make the necessary responses. Furthermore, we measure the operating environment on a continual basis as part of our safety management.

Disaster Drill

We conduct a disaster drill twice a year at all our business bases under the scenario that a fire or an earthquake has occurred. Such drills are carried out with the simulated damage specifically related to each business bases. The drills include AED use training, injury transportation training, and firefighting training so that the participants can confirm the procedure of what they need to do promptly at the time of an emergency. The challenges identified through these drills are scrutinized at each business base in order for them to be more resilient to disasters.

Auditing

Audits focus on confirmation that the EHS management system is properly prepared and operates in conformity with the ISO requirements, related laws and regulations are observed, and the management system performs effectively for operations.

| External audit | To ensure proper operation of the management system in conformity with ISO14001 and 45001, we receive a review by an external certifying organization annually. |

|---|---|

| Internal audit | Self-inspections are conducted to see if our performance is in accordance with the internal regulations set based on ISO14001 and 45001 to confirm the system’s conformity and compliance with the regulations (twice a year). |

Management Review (by the Top Management)

We conduct a management review as an opportunity for the top management to review the results of our EHS commitments.

Based on the auditing results obtained both externally and internally, and also on customer needs, the top management judges the appropriateness and effectiveness of a wide variety of activities that we have implemented to achieve our targets, and our performance. By doing so, the top management is striving to improve the management system on a continual basis.

Performance Evaluation

For our performance evaluation conducted for specific efforts, such as waste management and energy management, please see the links below.

Environment

Occupational Safety and Health and Anti-Disaster Measures at Overseas Bases

| Overseas factories | Themes | Overview |

|---|---|---|

| Noven | Occupational safety and health | As part of its new employee orientation, Noven provides an overview of its EHS activities on the first day of employment. The overview includes safety objectives, injury reporting, evacuation procedures, and security protocols. It also holds monthly safety lectures on topics such as lifting techniques to prevent back pain, machine guards, and heat stroke prevention. In addition, it provides training on how to provide cardiac life support, how to use an AED in an emergency, and how to perform basic first aid skills. |

| Disaster preparedness | Targeting all employees at risk of falling, Noven provides training on topics such as the nature and identification of fall hazards, minimization of fall hazards, types and limitations of fall protection equipment, and inspection of fall protection equipment. | |

| Hisamitsu Indonesia | Occupational safety and health | Hisamitsu Indonesia works to prevent occupational accidents through regular patrols conducted by safety and health committee members. |

| Disaster preparedness | At the factory and headquarters in Sidoarjo, Hisamitsu Indonesia conducts evacuation drills that simulate fires and earthquakes. It also performs life-saving drills so that its employees can take appropriate and prompt action in the event of an emergency. | |

| Hisamitsu Vietnam | Occupational safety and health | Hisamitsu Vietnam regularly provides occupational safety education by external instructors to employees on production lines and warehouses that use elevators. |

| Disaster preparedness | Hisamitsu Vietnam conducts firefighting and life-saving drills under the guidance of the firefighting and public security authority of the Dong Nai Province. It conducts fire extinguishing drills using fire extinguishers, training in primary life-saving skills, and water-discharge drills using water hoses to prepare for initial firefighting and primary life-saving actions in the event of an emergency. | |

| Hisamitsu Brazil | Occupational safety and health | With the aim of reducing the potential risk of occupational accidents, Hisamitsu Brazil has introduced an ISO45001 management system to provide safety and health education to operators of manufacturing equipment and facilities and those who handle chemical products and drugs. It also creates a comfortable workplace and living environment based on ergonomics. |

| Disaster preparedness | Hisamitsu Brazil conducts a monthly inspection of fire extinguishers and hydrants on the premises. In addition, under the guidance of a disaster prevention trainer, it regularly conducts firefighting and disaster prevention drills for its in-house fire unit members. |